Ridgewater Homeowner Grinder Pump Maintenance Package

Dear Ridgewater Residents,

A grinder maintenance package is hereby made available online to all current and future residents to serve several important purposes:

- Comply with Ridgewater CC&R Policy, guidelines, and directives.

- Prolong Equipment Life: Regular maintenance helps identify and address issues before they lead to significant damage, extending the lifespan of the grinder.

- Ensure Optimal Performance: Routine checks and adjustments ensure that the grinder operates at peak efficiency, resulting in better quality output and reduced downtime.

- Prevent Breakdowns: Scheduled maintenance can help prevent unexpected breakdowns, which can be costly in terms of repairs and lost productivity.

- Safety Assurance: Regular maintenance checks can identify safety hazards, ensuring that the equipment operates safely and complies with industry standards.

- Cost Efficiency: By maintaining the grinder regularly, businesses can avoid expensive repairs and replacements, ultimately saving money in the long run.

- Maintain Warranty Compliance: Many manufacturers require regular maintenance to keep warranties valid, so a maintenance package can help ensure compliance.

- Documentation and Record Keeping: A maintenance package often includes documentation of all services performed, which can be useful for audits or resale purposes.

Overall, a grinder maintenance package is essential for maintaining the reliability, efficiency, and safety of the equipment. To service all of the homes in our community, Tech Plumbing is our new licensed vendor. McCall Brothers is no longer servicing our community.

Basic Information Homeowners Should Know About Grinder Pumps

As a homeowner, it is important that you know what equipment is responsible for properly removing wastewater from your house?

Grinder pumps are used in neighborhoods like Ridgewater, where site conditions such as building elevations and ground slopes make construction of conventional ‘gravity sewers’ impractical.

A grinder pump is used to grind up and pump out wastewater from your home to the main sewer system. It is usually installed in a basin in the ground outside of your home. The pump has sharp blades that macerate the waste into a slurry that can then be pumped uphill to a gravity sewer line or directly to a treatment plant. These pumps require electricity to operate and run automatically based on the level of waste in the basin.

Grinder pumps made the development of your neighborhood and home possible. Your grinder pump system safely and efficiently pumps wastewater (also known as ‘sewage’) created inside your home into the wastewater collection and treatment system serving your property.

For those unfamiliar with grinder pump systems, these sewage ejector pumps grind up waste and push it out to the main sewer line since natural gravity flow isn’t possible. Proper maintenance of your grinder pump is essential to avoid clogs, overflows, and expensive repairs down the road

Components of A Grinder Pump:

a) Pump Basin

The pump basin is a watertight container that houses the grinder pump and collects wastewater from the connected plumbing. It acts as a reservoir, allowing the pump to operate efficiently by providing a consistent supply of wastewater to be ground and pumped.

b) Piping and Valves

Piping and valves are essential for directing the flow of wastewater from the pump basin to the force main. The piping carries the ground wastewater to the discharge point, while valves control the flow and can isolate sections of the system for maintenance or emergencies.

c) Floats

Floats are used to monitor the water level within the pump basin. They activate the grinder pump when the wastewater reaches a certain level, ensuring that the pump operates only when necessary. This helps prevent overflow and maintains proper system function.

d) Electrical Wiring from Pump Unit to Control Panel

This wiring connects the grinder pump to the control panel, providing power to the pump and allowing for communication between the pump and the control system. It ensures that the pump can be activated and deactivated based on the signals received from the floats.

Force Main from Pump Unit to Cut-Off Valve at the Public Right-of-Way

The force main is the pressurized pipe that transports the ground wastewater from the grinder pump to the discharge point, typically at a public sewer line. The cut-off valve allows for maintenance and control of the flow in the force main.

f) Grinder Pump

The grinder pump is the core component that grinds solid waste into a slurry and pumps it through the force main. It is designed to handle both liquid and solid waste, making it suitable for residential or commercial wastewater systems where gravity drainage is not feasible.

g) Control Panel

The control panel houses the electrical components that manage the operation of the grinder pump. It receives signals from the floats, controls the pump’s operation, and may include alarms for system malfunctions, such as high water levels or pump failures.

Alarm Box. The purpose of an alarm box in a grinder sewer system is to monitor the operation of the grinder pump and alert users to any malfunctions or issues. Here are the key functions of the alarm box:

- Monitoring: It continuously checks the performance of the grinder pump, ensuring it operates within specified parameters.

- Alerting: If the pump fails to operate correctly, such as if it becomes clogged or if there is a power failure, the alarm box will trigger an audible or visual alarm to notify users of the problem.

- Preventing Damage: By alerting users to issues early, the alarm box helps prevent potential damage to the pump and the sewer system, reducing the risk of costly repairs and backups.

- Maintenance Reminder: Some alarm boxes may also provide indicators for routine maintenance needs, helping to ensure the system remains in good working condition.

Overall, the alarm box plays a crucial role in the safe and efficient operation of a grinder sewer system.

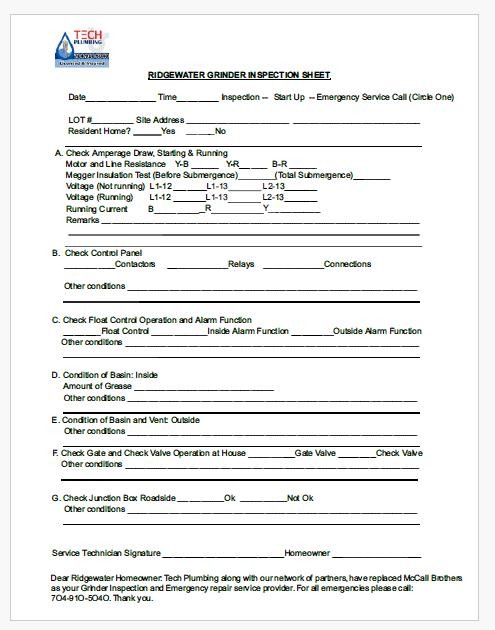

Annual Inspection and Maintenance:

To help maintain community-wide standards and quality of life, the homeowners’ association has hired a licensed inspector to conduct annual

inspections of the Grinder Pump Sewage System for all homes. If repairs are needed due to normal wear and tear, the association will cover the costs. The annual inspection will consist of the following:

Inspecting the various components of a grinder pump is essential for ensuring its efficient operation and longevity. Here’s a breakdown of the purpose of inspecting each component you mentioned:

a) Check amperage draw, starting and running: This helps to determine if the pump is operating within its designed electrical parameters. Abnormal amperage can indicate issues such as motor overload, mechanical binding, or electrical problems, which could lead to pump failure if not addressed.

b) Check float control operation and alarm function: The float control system regulates the pump’s operation based on the water level in the wet well. Ensuring it functions correctly prevents overflows or dry running. The alarm function alerts operators to any malfunctions, allowing for timely intervention.

c) Clean wet well of grease build-up: Grease and debris accumulation can hinder the pump’s performance, leading to clogs or reduced efficiency. Regular cleaning ensures optimal flow and prevents operational issues.

e) Check gate and check valve operation: These valves control the flow of wastewater and prevent backflow. Inspecting their operation ensures that the pump can effectively move waste without obstruction, which is crucial for system reliability.

Overall, these inspections are part of a preventative maintenance strategy that helps avoid costly repairs, ensures the system operates effectively, and extends the lifespan of the grinder pump.

Basic Information Homeowners Should Know About Grinder Pumps

Your Role In Understanding Your Responsibility and What The Grinder Pump Can’t Do

As previously stated, if repairs are needed due to normal wear and tear, the association will cover the costs. However, if the inspection discloses that repairs are needed due to misuse by the homeowner, you, the homeowner, will be responsible for the costs.

To give you some idea of the cost of the grinder in advance, please know a brand new replacement grinder costs between $2,000 to $2,500, plus installation. Any replacement charges for new grinders or repairs can become liens against the property if not paid.

Therefore, please be advised that the grinder pump is not built to handle non-sewage waste. Again, if repairs are needed due to misuse by the homeowner, the homeowner will be responsible for the costs. Any charges for repairs can become liens against the property if not paid.

For these reasons, you should not drain or flush these types of items, which may clog or damage your grinder pump:

- Wet-wipes (baby, make-up, personal, etc.)

- Diapers

- Rags or cloths

- Cooking grease

- Feminine hygiene products

- Birth control products

- Dental floss

- Cat litter

- Plastic objects (toys, utensils, etc.)

- Glass

- Metal

- seafood shells

- Aquarium stone

- Motor oil

- Gasoline or combustible liquids

- Corrosive chemicals

To Explain Even Further:

Grinder pumps are designed to handle wastewater and sewage, but certain items can cause significant harm to them. Here’s how each of the listed items can negatively impact a grinder pump:

Diapers: These are bulky and absorbent, leading to clogs. They can easily jam the grinder mechanism, causing it to overheat or fail.

Rags or Cloths: Similar to diapers, these can entangle in the pump’s impeller, obstructing its movement and potentially damaging the motor.

Cooking Grease: Grease can solidify in the pipes and pump, leading to blockages. It can also coat the internal components, reducing efficiency and causing overheating.

Feminine Hygiene Products: These products are designed to absorb fluids and can expand, leading to clogs and potential pump failure.

Birth Control Products: Items like condoms can tangle in the pump or create blockages, disrupting normal operation.

Dental Floss: This can wrap around the impeller or other components, causing jams and reducing the pump’s effectiveness.

Cat Litter: Many types of cat litter absorb moisture and can create clumps, leading to blockages in the pump and pipes.

Plastic Objects (Toys, Utensils, etc.): These can physically obstruct the pump’s mechanisms, leading to mechanical failure or damage.

Glass: Glass can break into sharp pieces that can damage the pump or cause injuries during maintenance.

Metal: Similar to glass, metal objects can cause physical damage to the pump and its components.

Seafood Shells: These can be hard and abrasive, potentially damaging the pump’s blades and causing clogs.

Aquarium Stone: Heavy stones can obstruct the pump and cause wear and tear on the impeller.

Motor Oil: This can coat internal components, leading to reduced efficiency and potential overheating.

Gasoline or Combustible Liquids: These can create fire hazards and damage the pump’s materials, leading to catastrophic failure.

Corrosive Chemicals: These can degrade the materials of the pump, leading to leaks, failures, and potential environmental hazards.

To maintain the functionality and longevity of a grinder pump, it’s essential to avoid disposing of these items in the system. Proper disposal methods should be followed for all non-biodegradable and hazardous materials.

Best Practices Tech Plumbing Will Deliver At Each Grinder Tune-Up:

Check the Alarm Panel

The alarm panel on your grinder pump controls the unit and alerts you to any malfunctions. Inspect the panel to ensure all lights are working properly. The power on and ready lights should be illuminated, while the high level and overload lights should be off. Any other lights indicate an issue and require service.

Inspect the Discharge Pipe

The discharge pipe carries waste from the grinder pump out to the main sewer line. Check that the pipe shows no signs of leaks, cracks, or blockages. Clear the pipe of any debris like roots or sediment buildup. A clogged discharge pipe prevents proper functioning and risks overflowing into your yard or home.

Test the Emergency Backup System

In the event of a power outage, an emergency backup system will automatically start your grinder pump. Manually test this backup system by flipping the emergency backup switch on. The grinder pump should activate briefly before the switch automatically resets to auto/off. If the backup system does not activate the pump, schedule service immediately to avoid problems during a power outage.

Pump Out the Wet Well

The wet well holds waste from your home before the grinder pump transports it to the sewer line. Pump out and thoroughly clean the wet well every 6-12 months to remove sludge and debris buildup, especially if you notice decreased water flow or gurgling sounds from drains. A full wet well reduces pumping efficiency and risks overflowing into your home.

System Ownership, Use, Maintenance and Repair

- Grinder Pump System, Generally. Ridgewater will utilize a low-pressure sewage collection and discharge system for the conveyance of sewage from each Dwelling to the public sewer system (“Public Sewer System”) serving Ridgewater. Each Dwelling will have a gravity flow sewage collection system (“Collection System”) which will pipe the sewage generated from such Dwelling into a buried collection tank located on the Lot (“Collection Tank”). The Collection Tank will house a simplex grinder pump with associated electrical equipment (“Grinder Pump”) that will process and pump fluids and solids into a PVC pipe which is connected to the Public Sewer System force main located in the public right of way fronting each Lot (“Force Main”). The Force Main will lead to a gravity sewer manhole where the sewage generated from the Dwelling will be discharged into the Public Sewer System for processing and treatment. Declarant will provide each initial Owner of each Dwelling an operation and maintenance package (“Maintenance Package”) for the Collection System, Collection Tank and Grinder Pump (collectively, the “Grinder Pump Sewage System”) at the initial closing on the Dwelling. The Association will maintain a copy of the Maintenance Package and homeowners purchasing resale homes in Ridgewater may obtain the Maintenance Package from the Association.